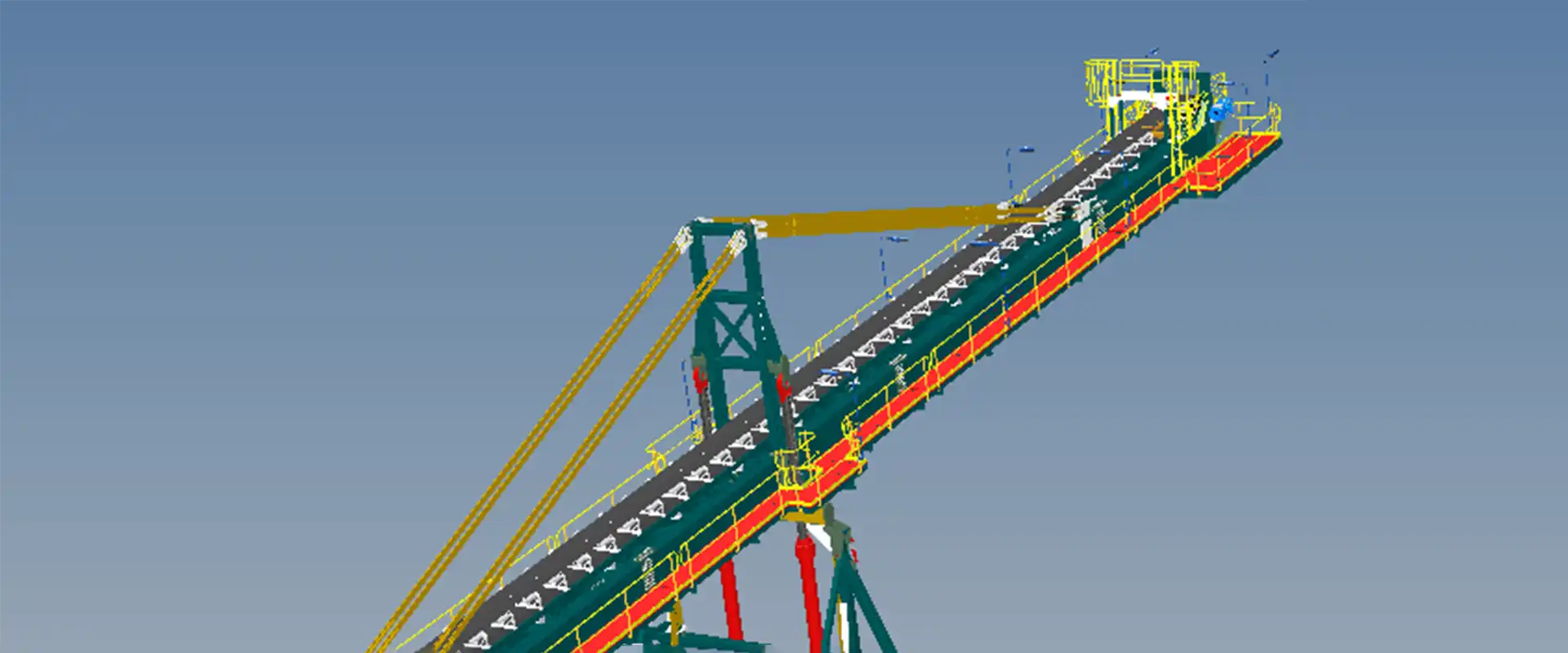

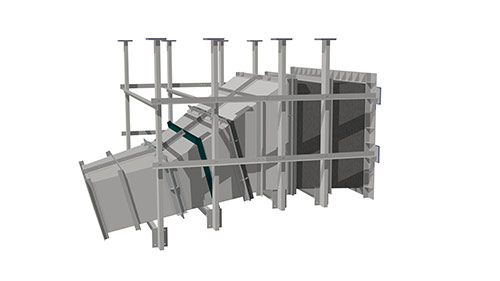

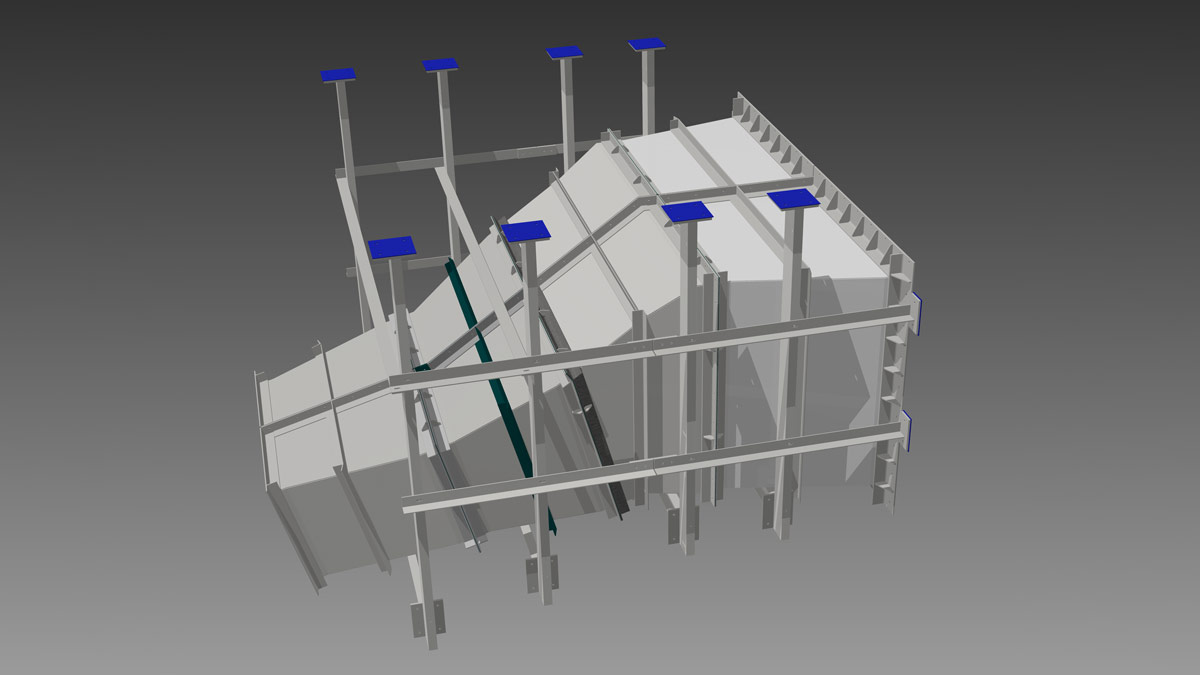

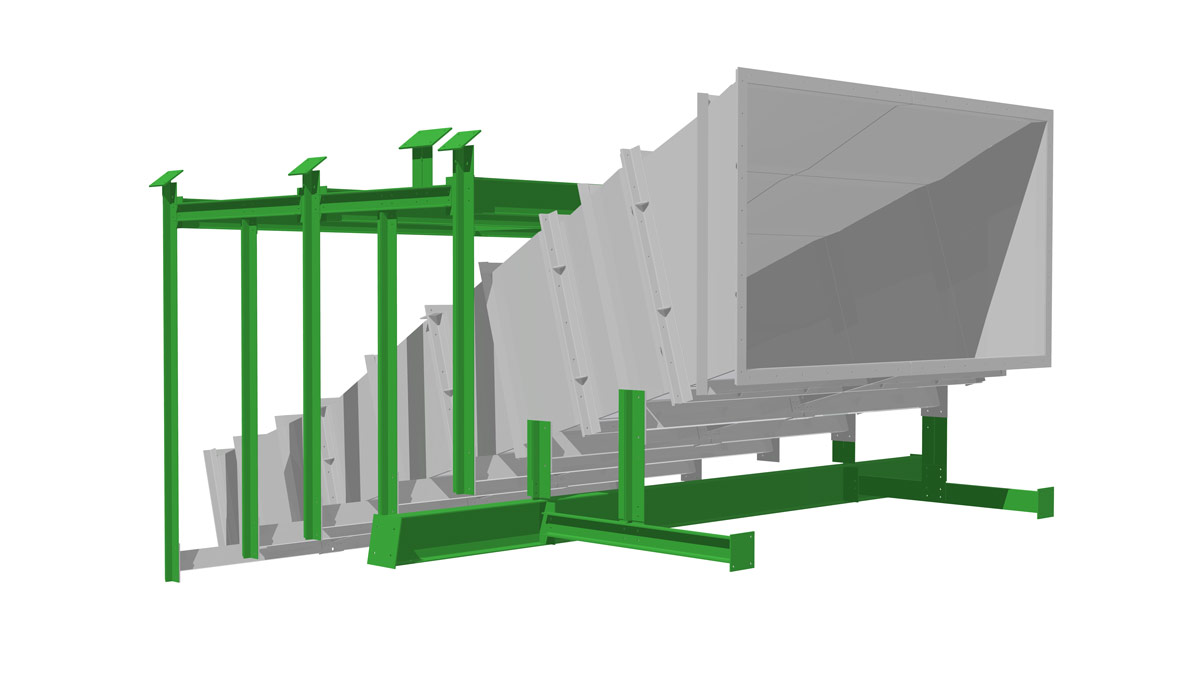

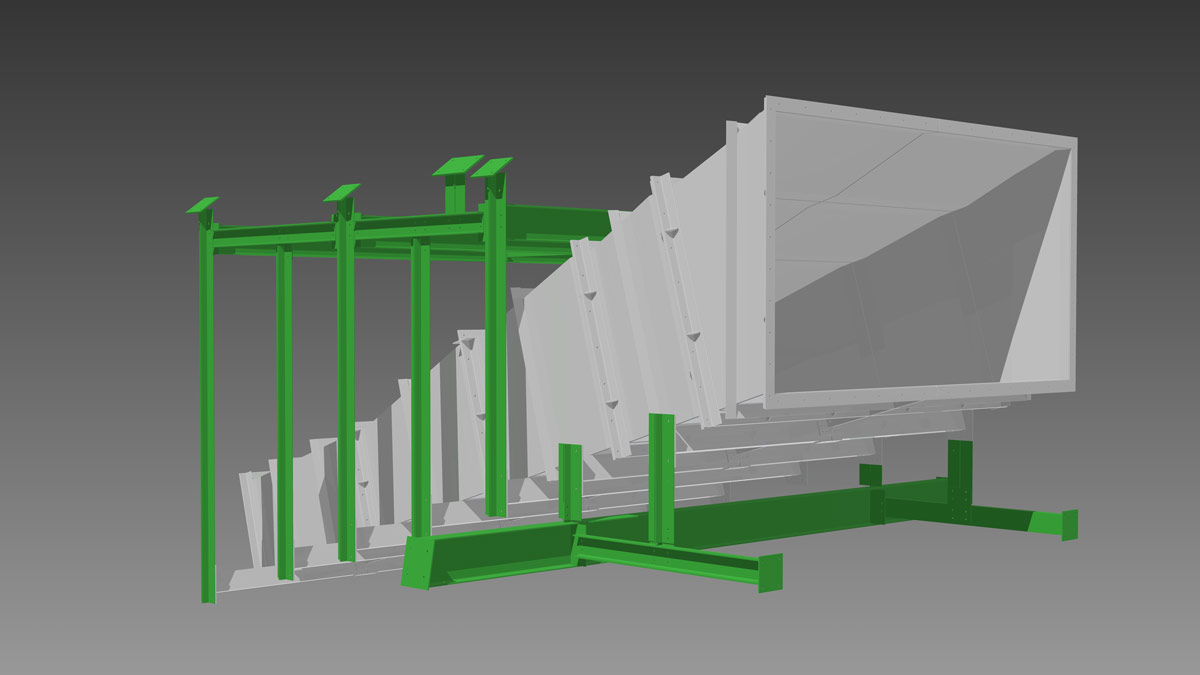

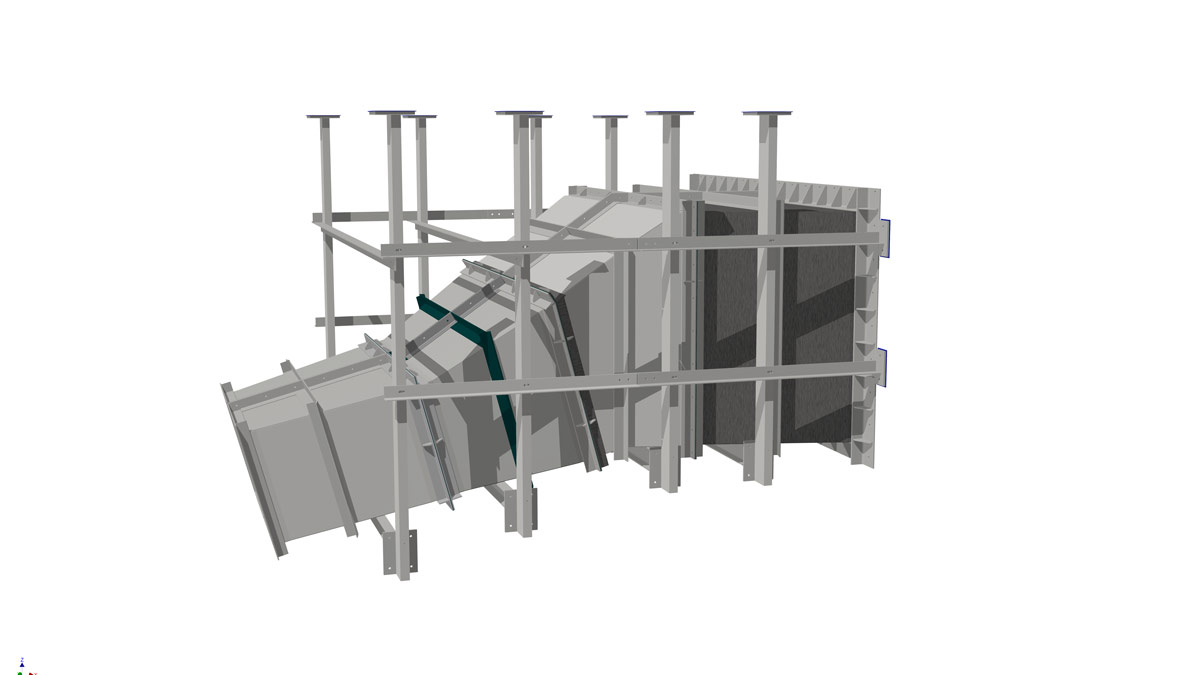

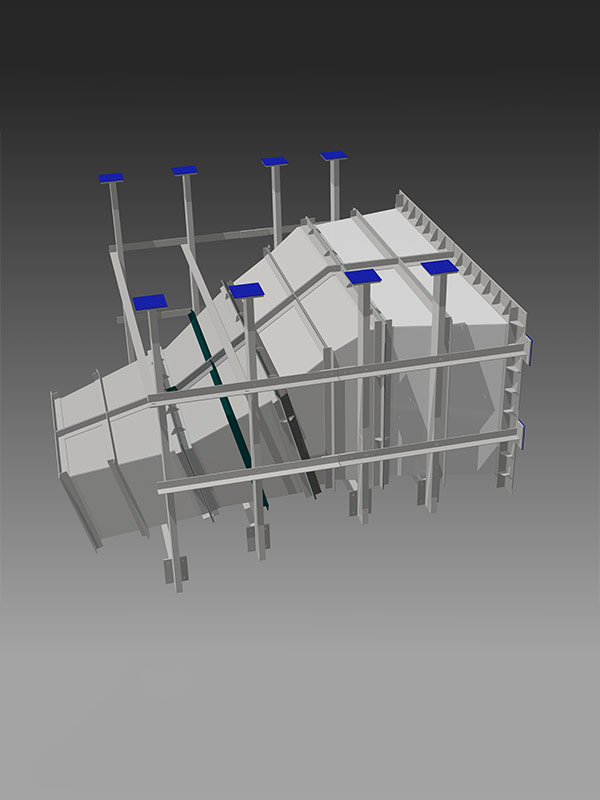

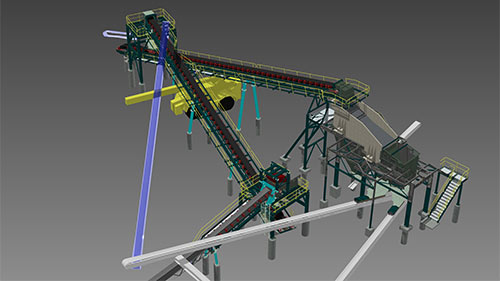

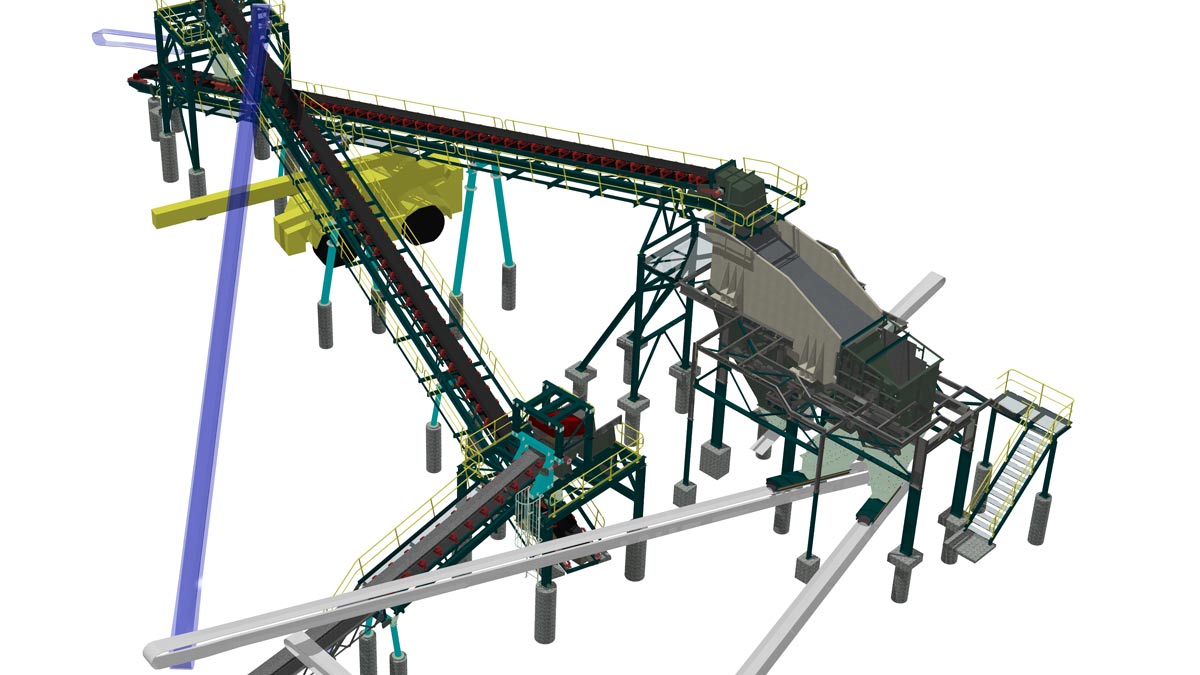

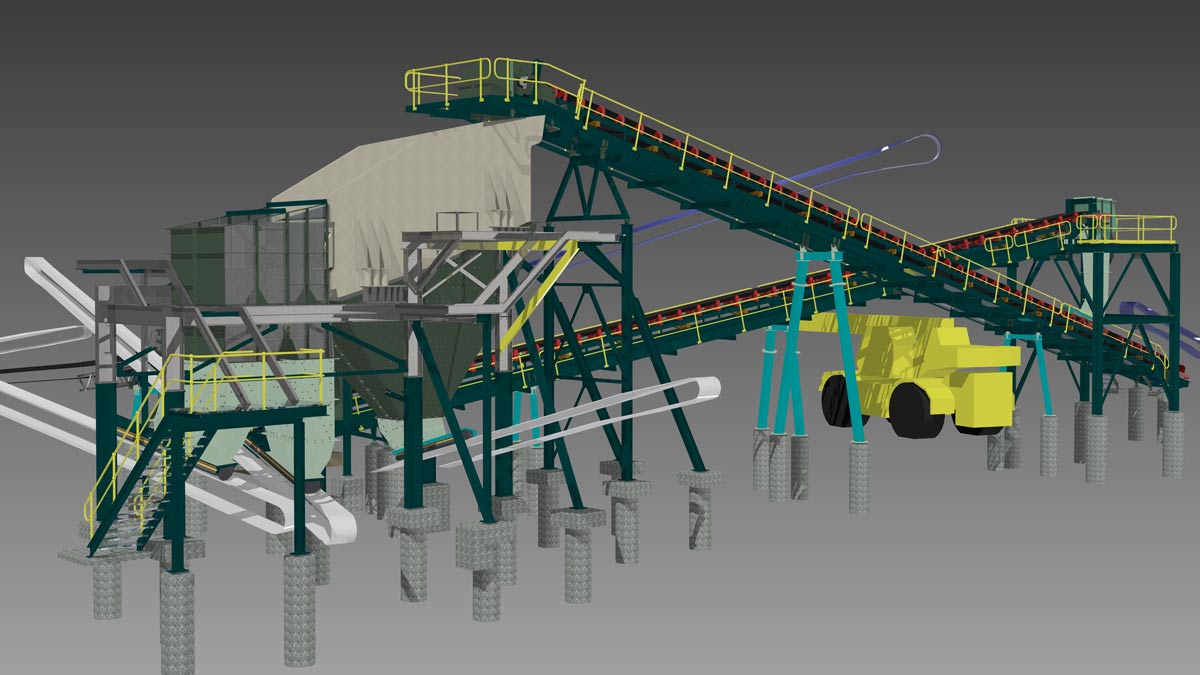

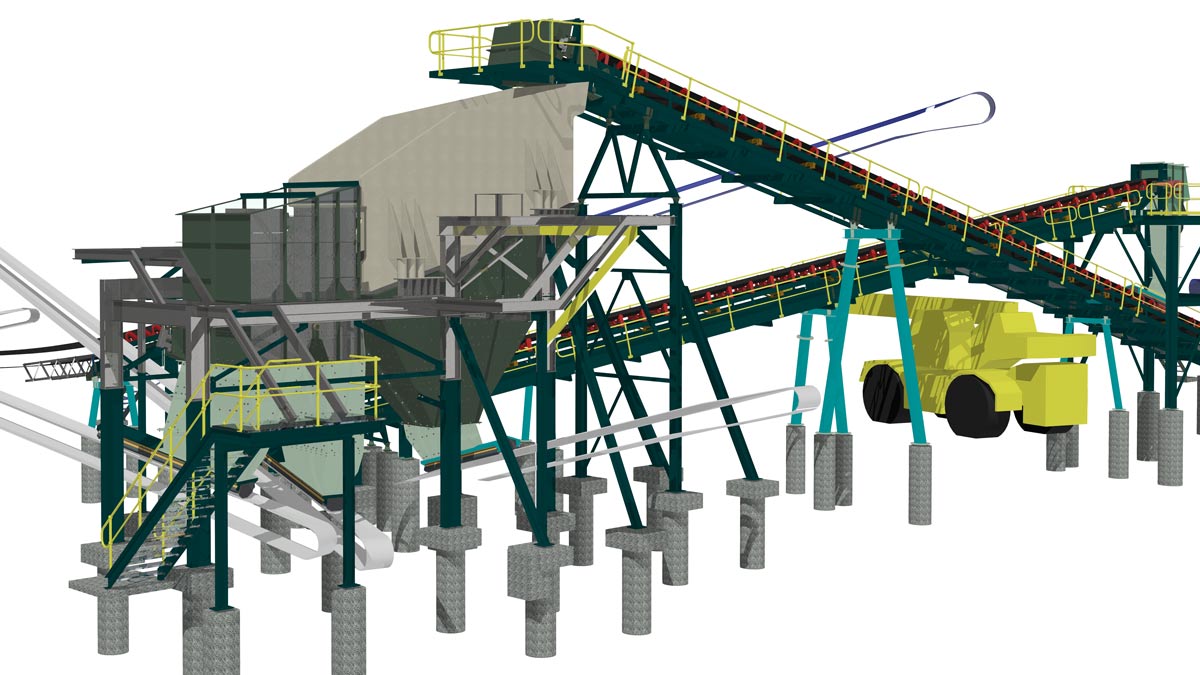

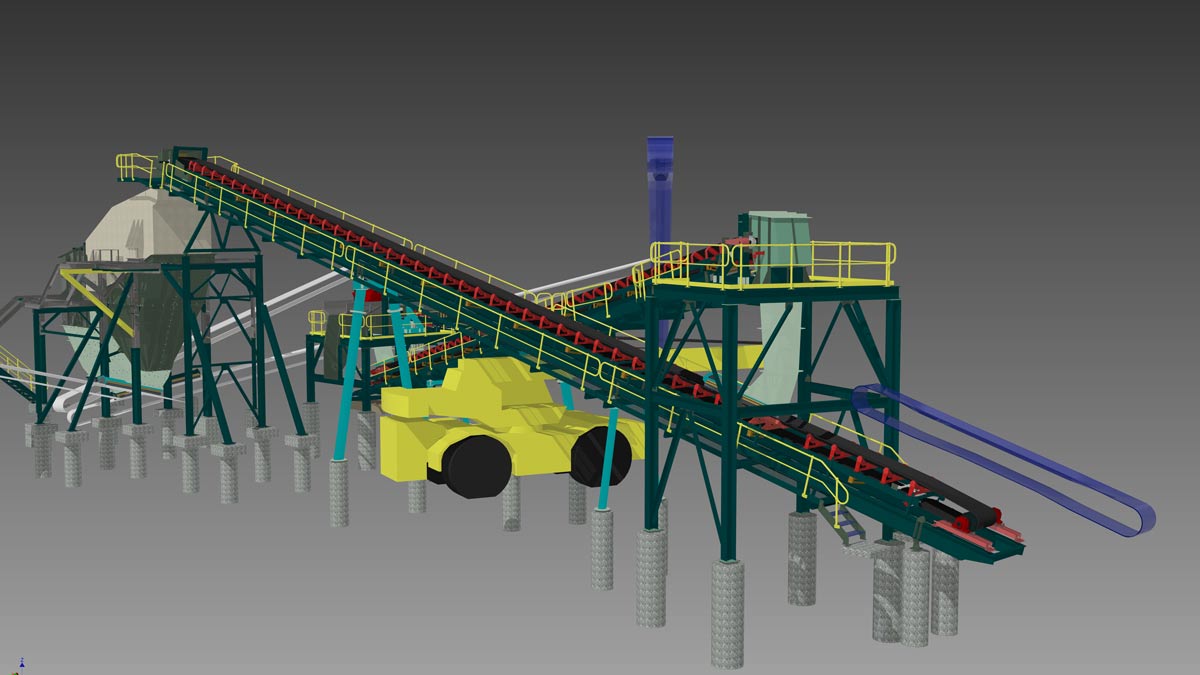

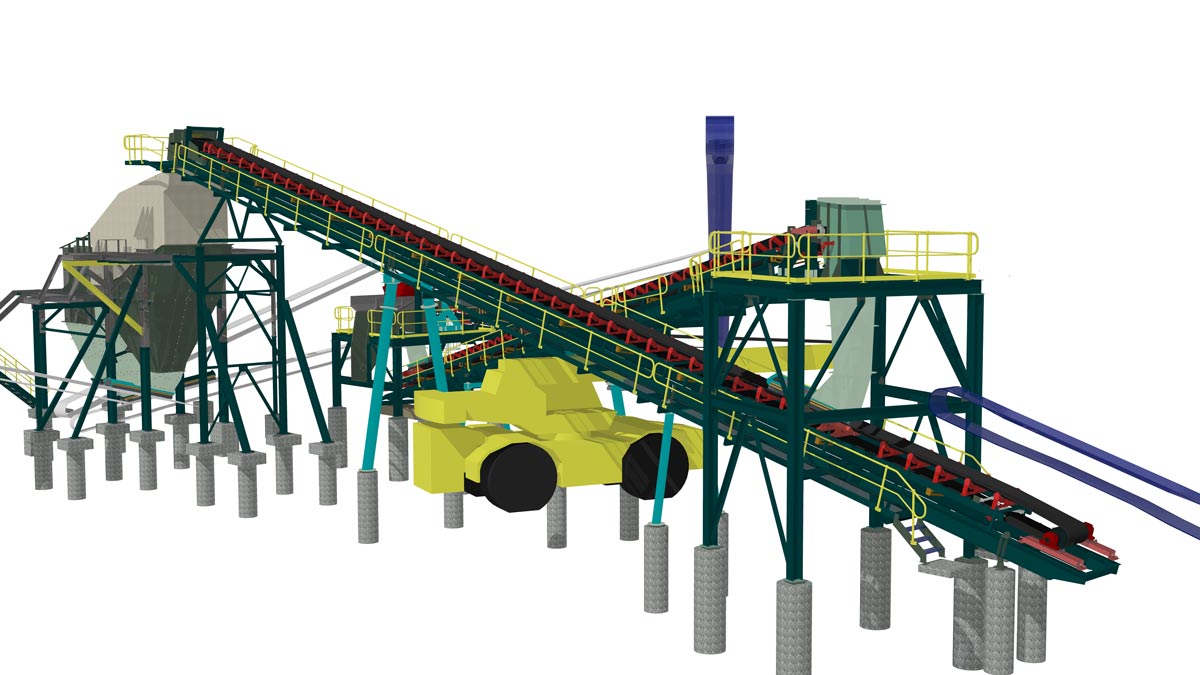

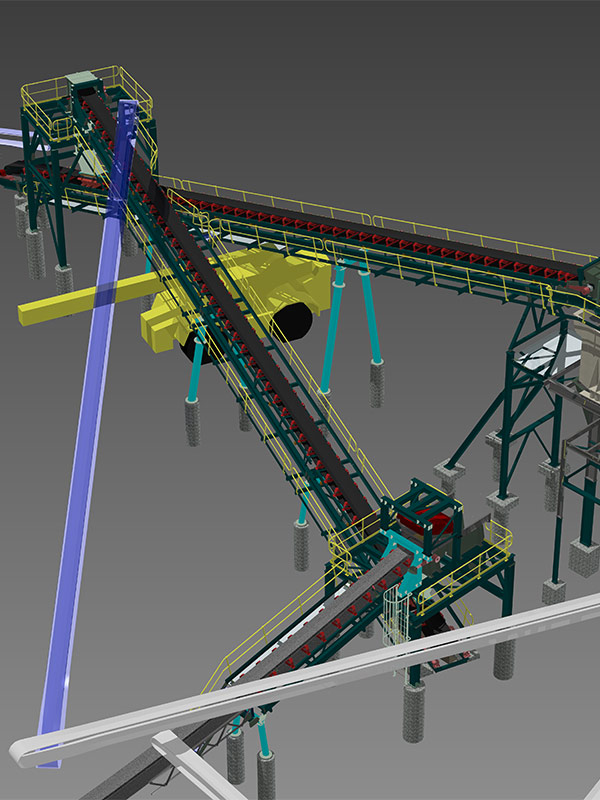

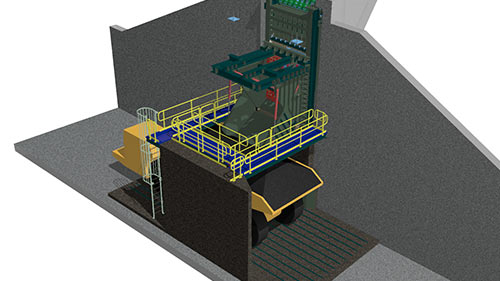

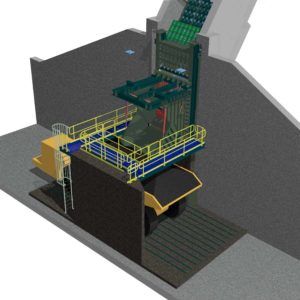

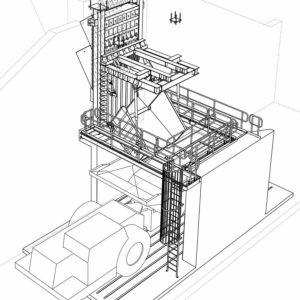

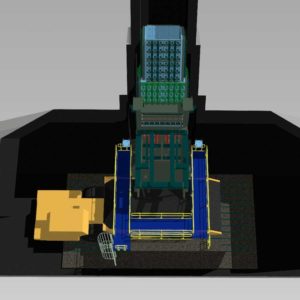

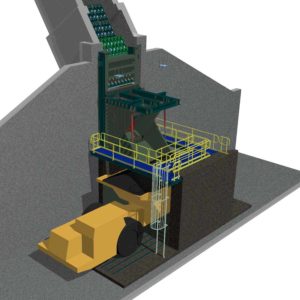

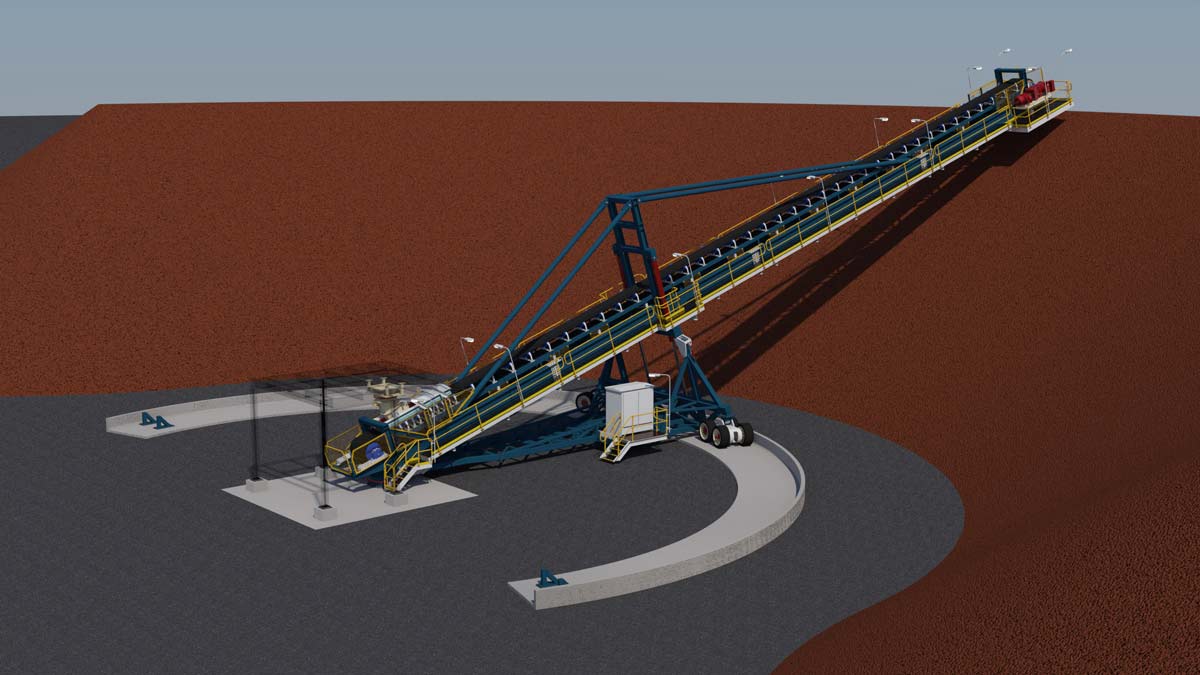

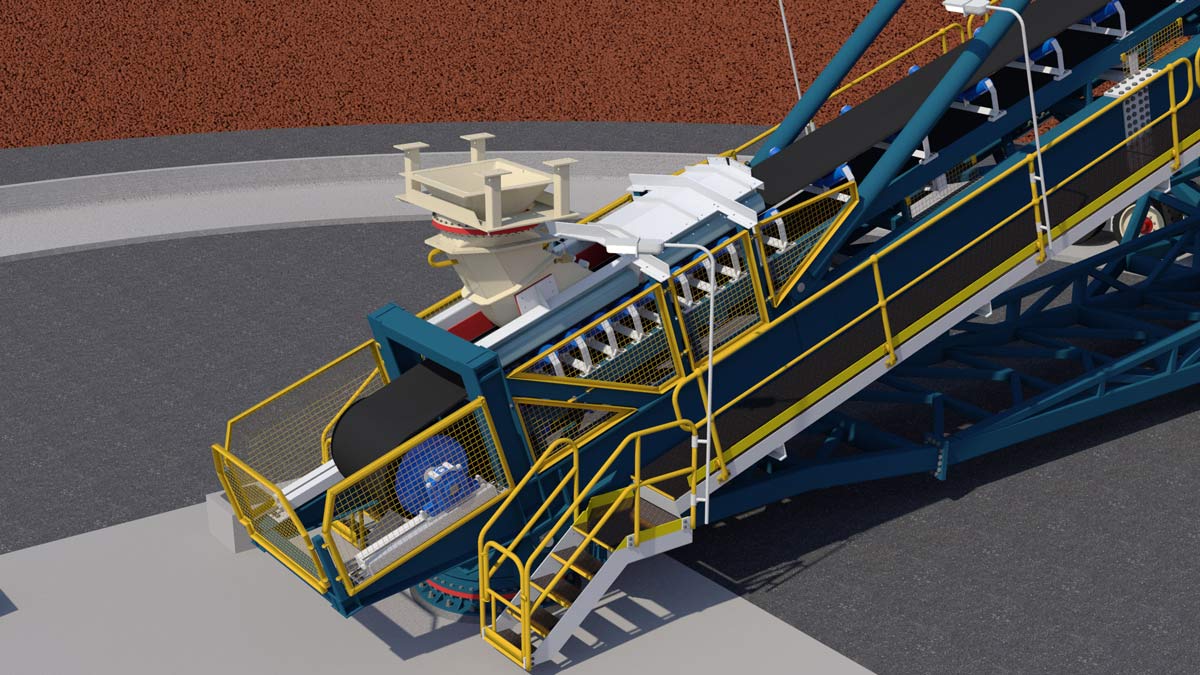

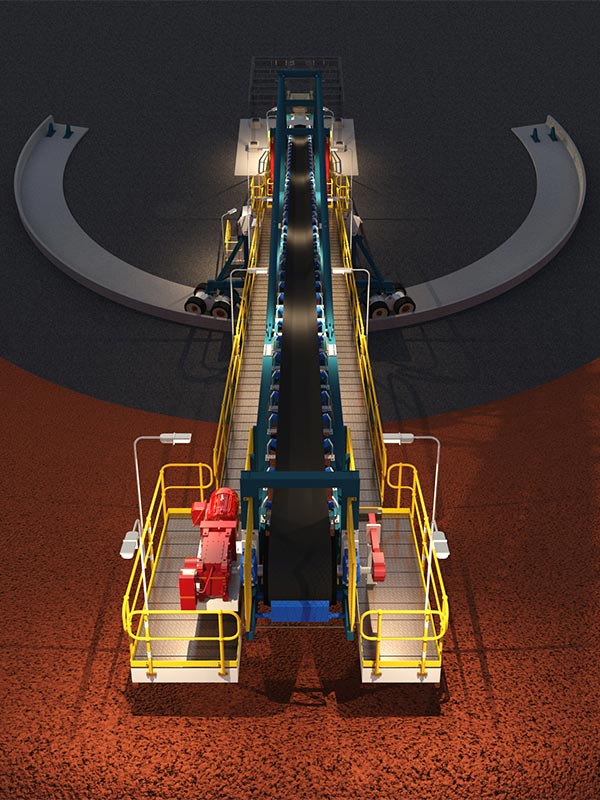

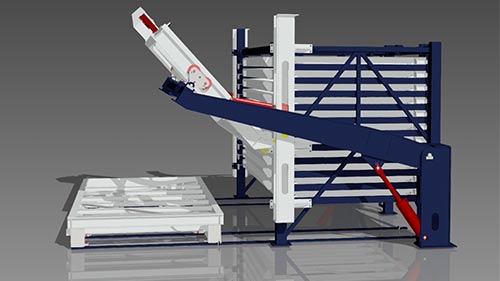

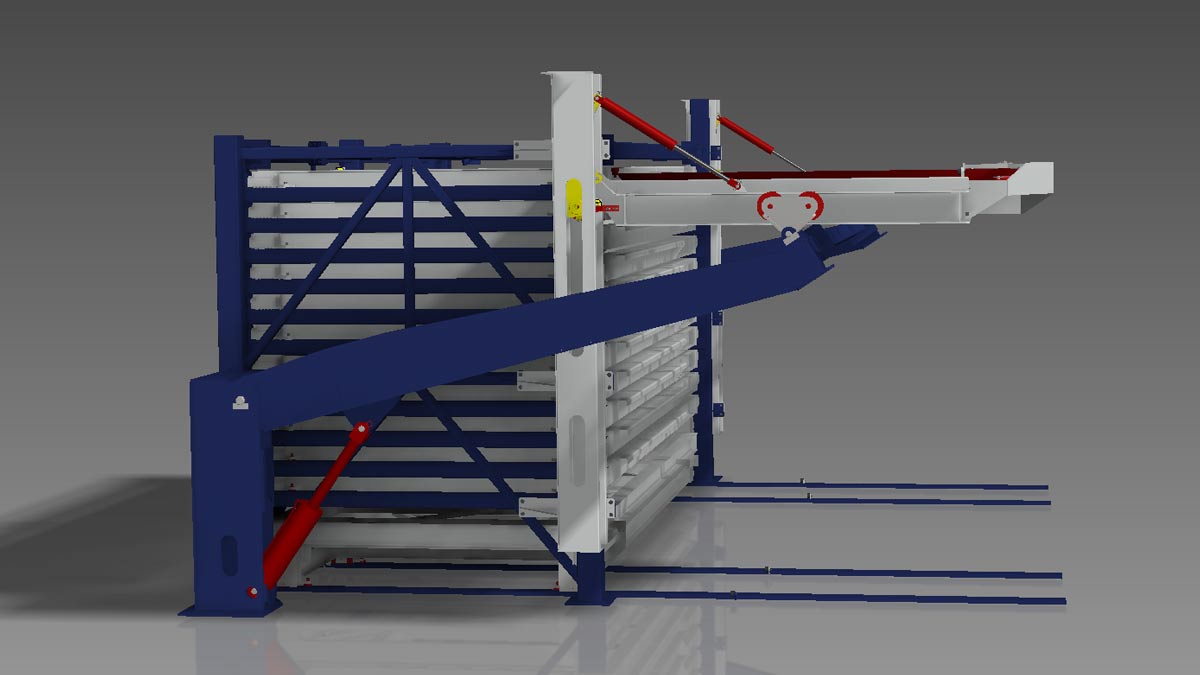

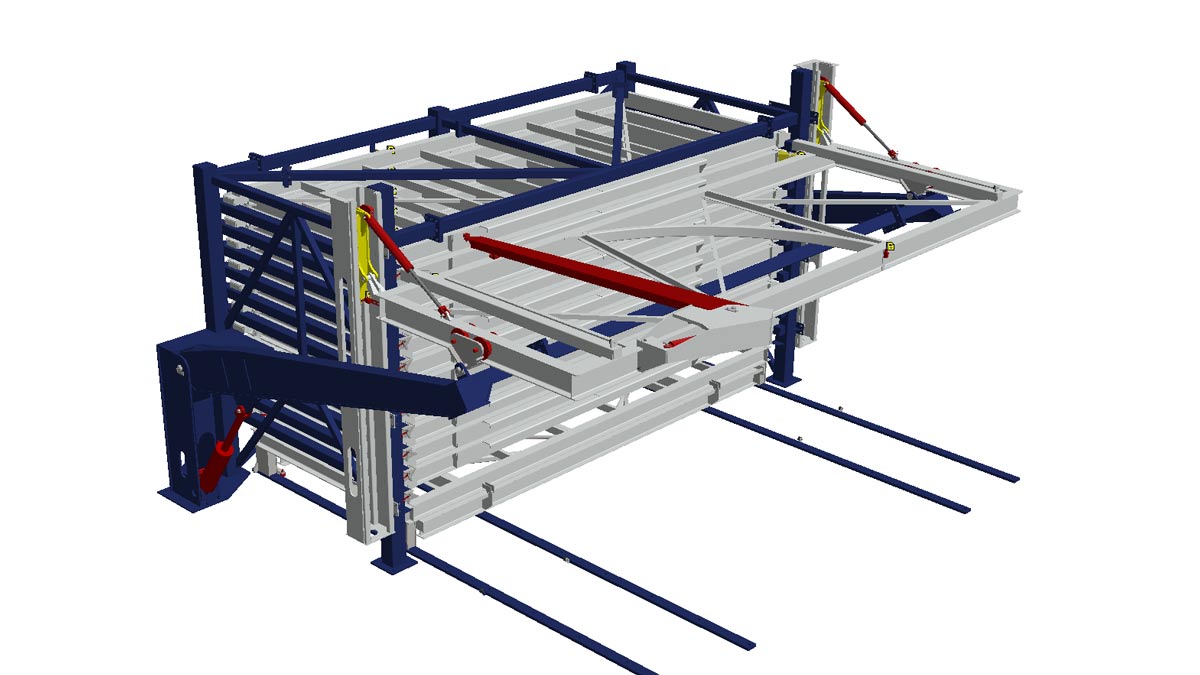

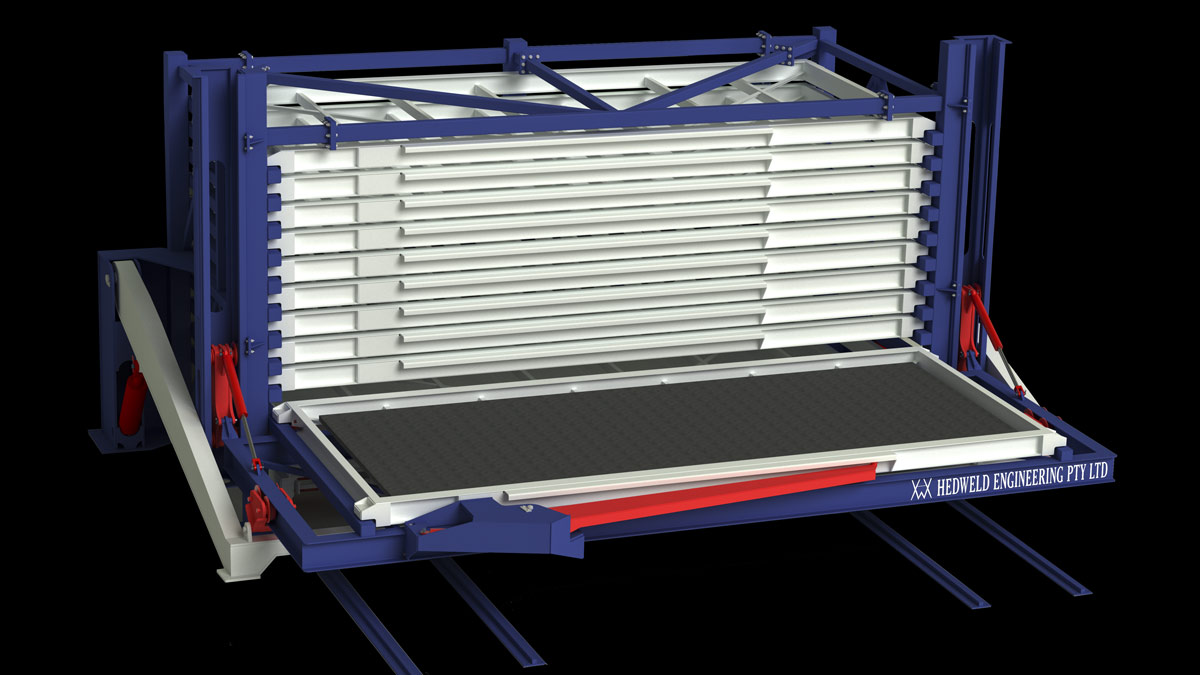

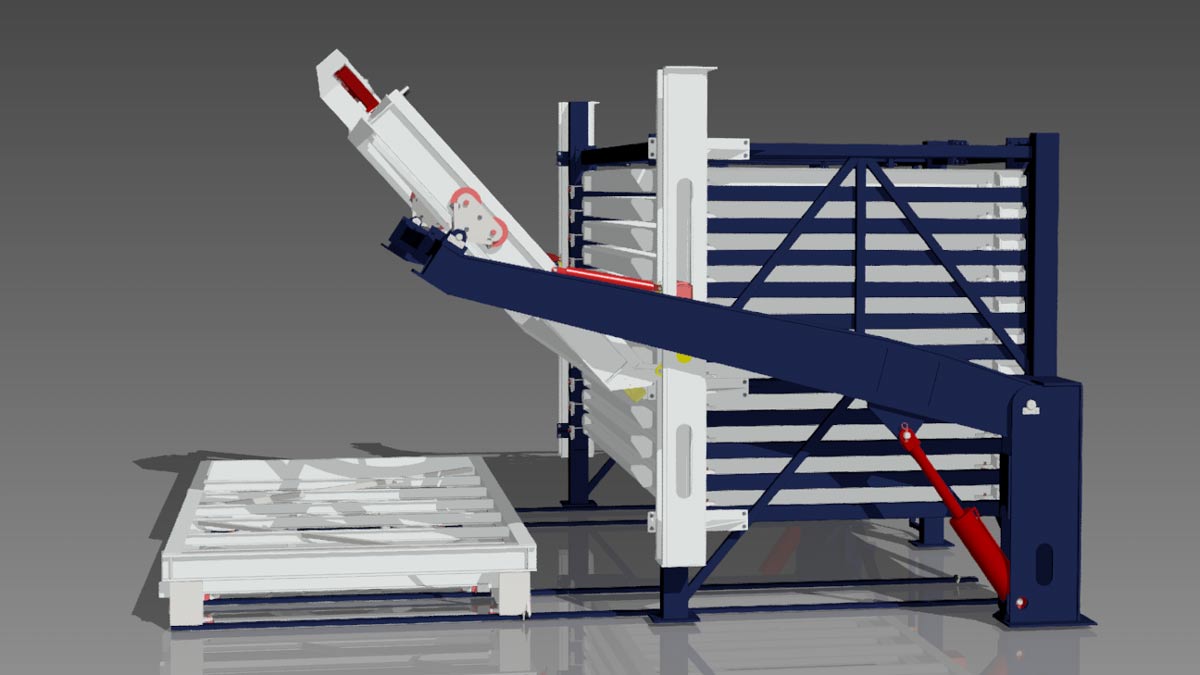

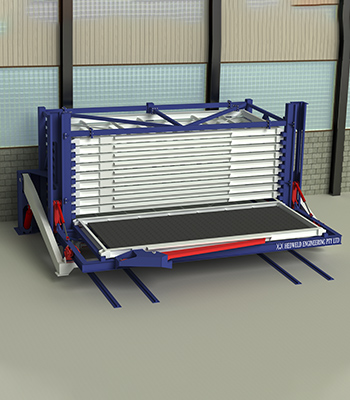

Formula 3D Engineering latest major design project is a new Radial Slewing and Luffing Stacker Conveyor for a ‘Clean Energy Resource’ Nickel mine in Western Australia. The Conveyor repositions from 7 deg to 16 degree through two main Lift Cylinders. The Conveyors unique feature is its mechanical locking arms which support the Conveyor in both of its working positions. This allows depressurising of it Hydraulic Lift system thus ensuring safe and reliable operation. The Slewing action is done by four Hydraulic Wheel Motors through an approximate Slewing angle of 180 degrees. Formula 3D Engineering does complete concept design through to full fabrication documentation. The Conveyor can move 230 tph of Nickel Ore and create a Stockpile 15m high with 22500 cubic metres of capacity.

New Company!

After almost 8 years operating under the Invent Design banner Formula 3D Engineering has decided to de-merge for Invent Design and operate as a single entity.

Continue reading